Pall Original Degas Module PN UDM-41110

- Stock: 1000

- Model: Pall Original Degas Module PN UDM-41110

- Weight: 30.00g

- SKU: 02.03.02.002.002

Pall Original Degas Module PN UDM-41110 Description

The UltiFuzor™ 41110 series degas module represents the latest advancement in Pall’s degassing technology. The UDM41110PT1 module enables digital inkjet printers to achieve high dissolved oxygen (DO) removal with minimal pressure drop, preventing bubble formation and ensuring optimal printer performance.

It runs with a max working pressure of 0.2MPa (30PSIG) and a max working temperature of 45℃(113℉) to ensure normal operation. Its larger design accommodates flow rate requirements up to 3L/min, making the UDM41110PT1 ideal for digital textile printing applications.

Pall Original Degas Module PN UDM-41110 Specifications

|

Product Name |

PALL Degas Module |

|

Product Model |

UDM-41110 |

|

Product material |

hollow fiber membrane |

|

Flow |

0-300ml/min |

|

Product introduction |

The UltiFuzor module is intended for use in a wide range of industrial ink jet printers to remove dissolved gasses, prevent bubble formation and assure printer performance. |

|

NOTE: |

Use with multiple inks is not recommended as ink compatibility interactions may reduce mold pillar performance or damage the mold pillar. Flushing or cleaning is not recommended. |

Shipping & Payment

|

Shipping Method |

DHL, FedEx |

Delivery Time |

1-3 working day after payment received |

|

Lead Time |

7 days or more |

Payment |

PayPal, Bank Transfer |

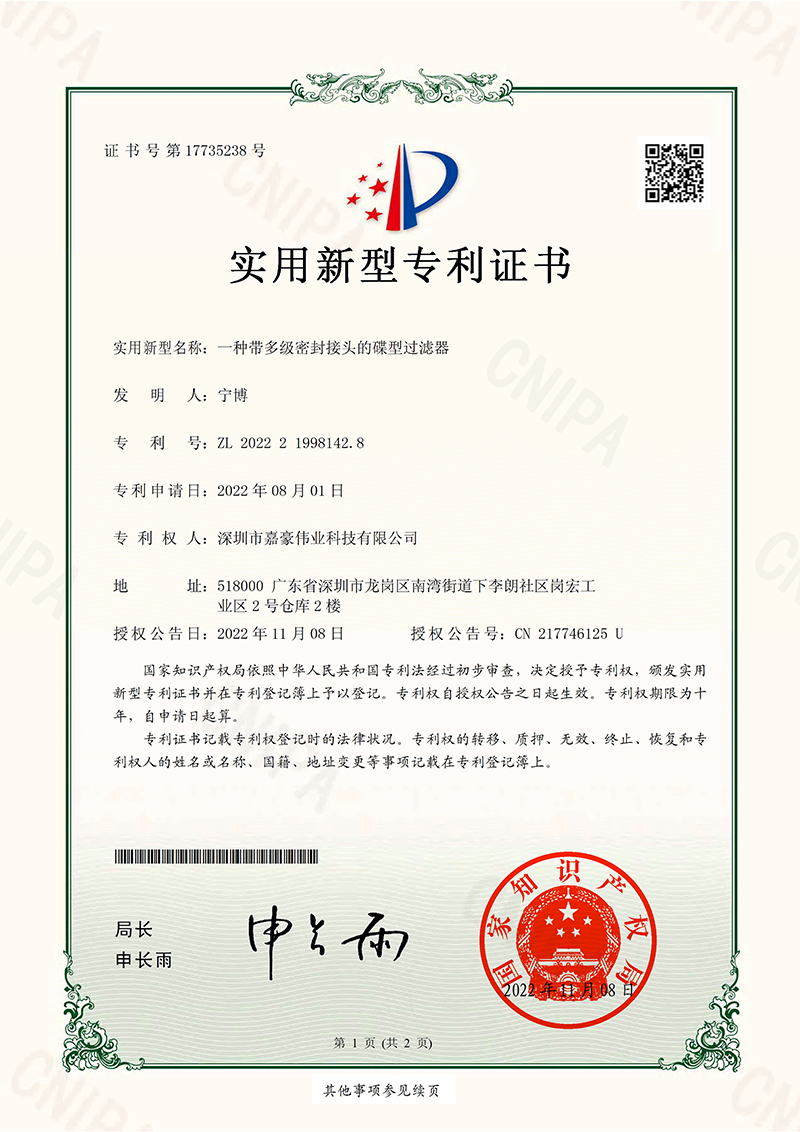

Certifications

Why Choose JOHOPE?

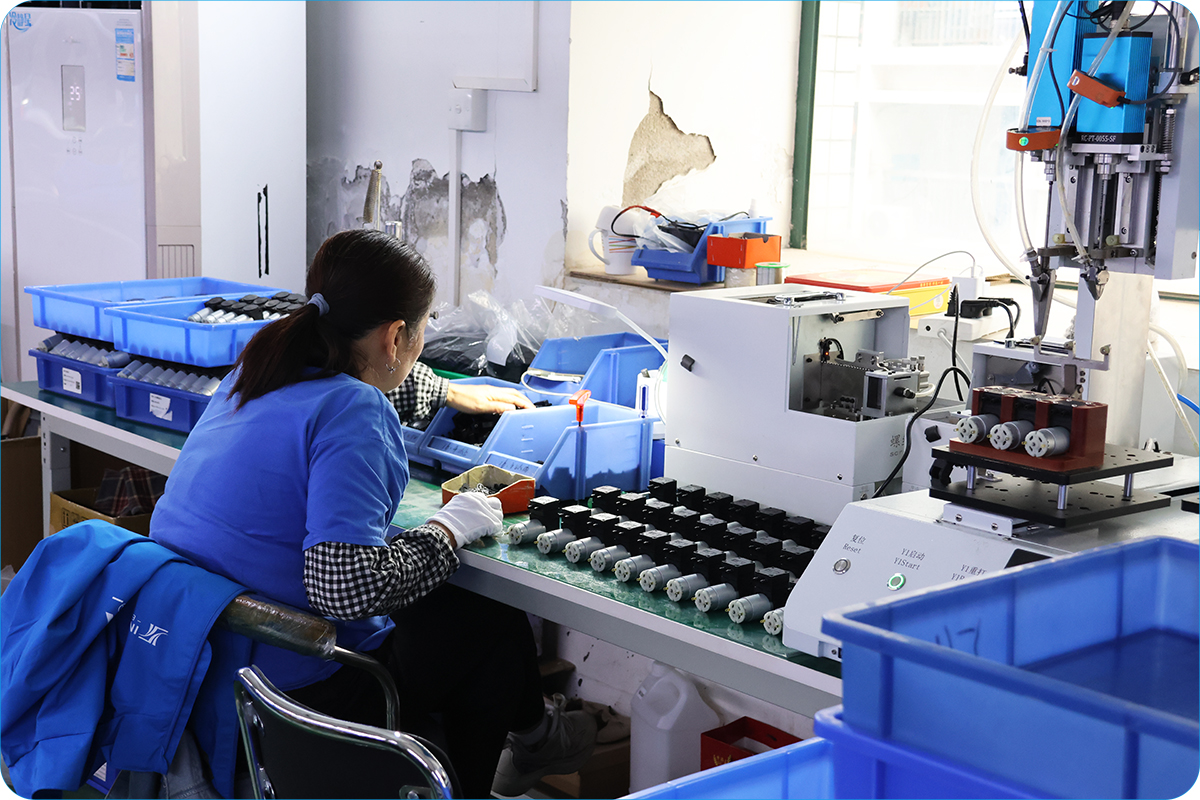

01 Professional Production Lines

- 5000+ high-quality products meet customers' specific requirements.

- Skilled workforce complies with standard production procedures & processes.

- R&D personnel possess extensive knowledge of printer ink supply parts.

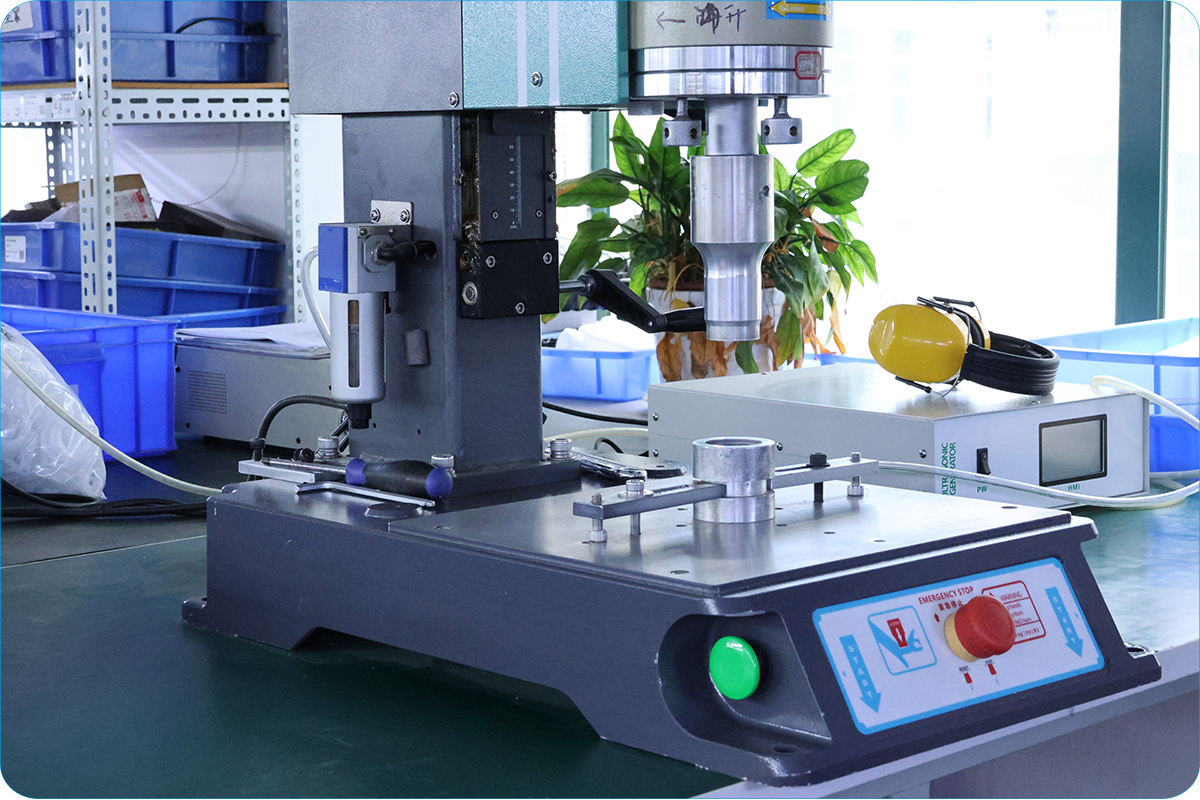

02 Automated Production Equipment

- Our company boasts cutting-edge production equipment that ensures precision and efficiency in every manufacturing process.

- The advanced machinery and production patent technology allow us to consistently deliver high-quality products that meet the demands of our clients.

03 Logistics and Warehousing

- Manage warehousing facilities to ensure product safety and traceability.

- Our warehouse covers a large area to ensure a complete inventory of products, realizing high product shipment efficiency.

- Years of production and sales experience have been highly recognized and praised by customers in the industry.

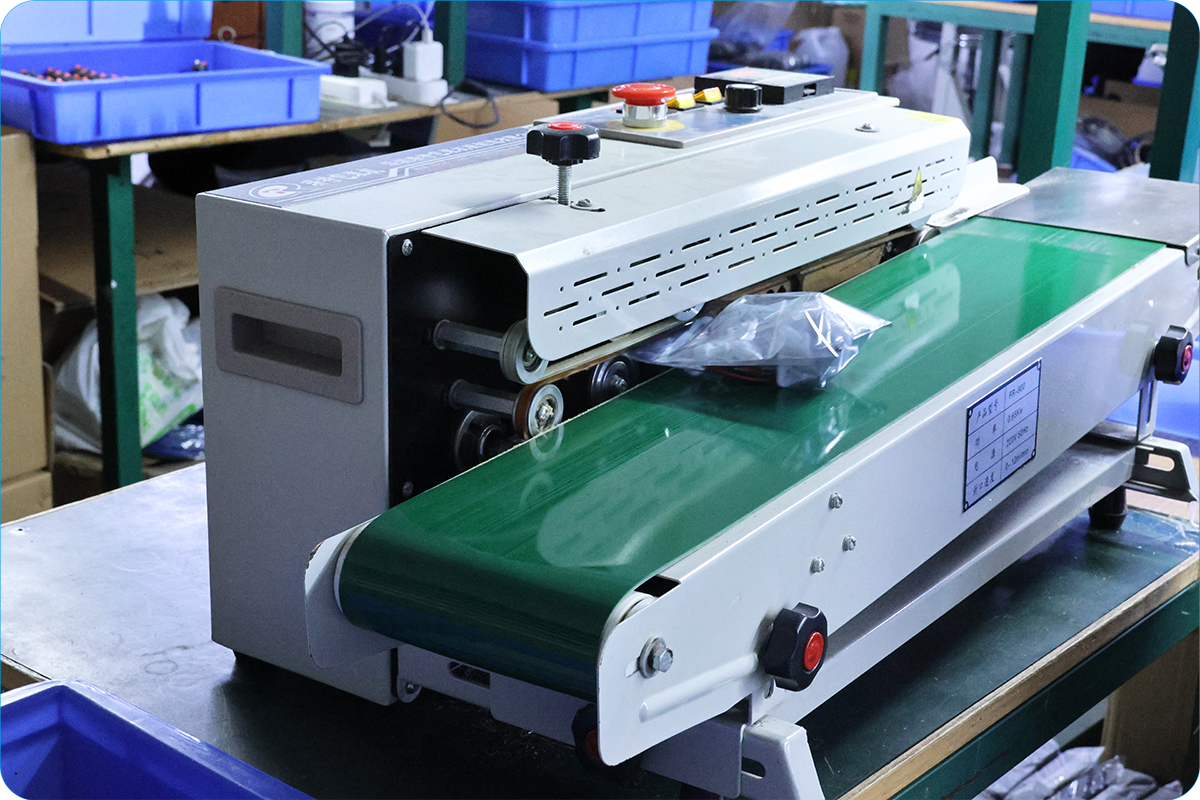

04 Reliable Packaging

- Our packaging solutions are designed with durability and precision to ensure each product is securely protected during transit.

- We use high-quality materials and advanced techniques to meet the specific needs of every order, guaranteeing safe and reliable delivery.

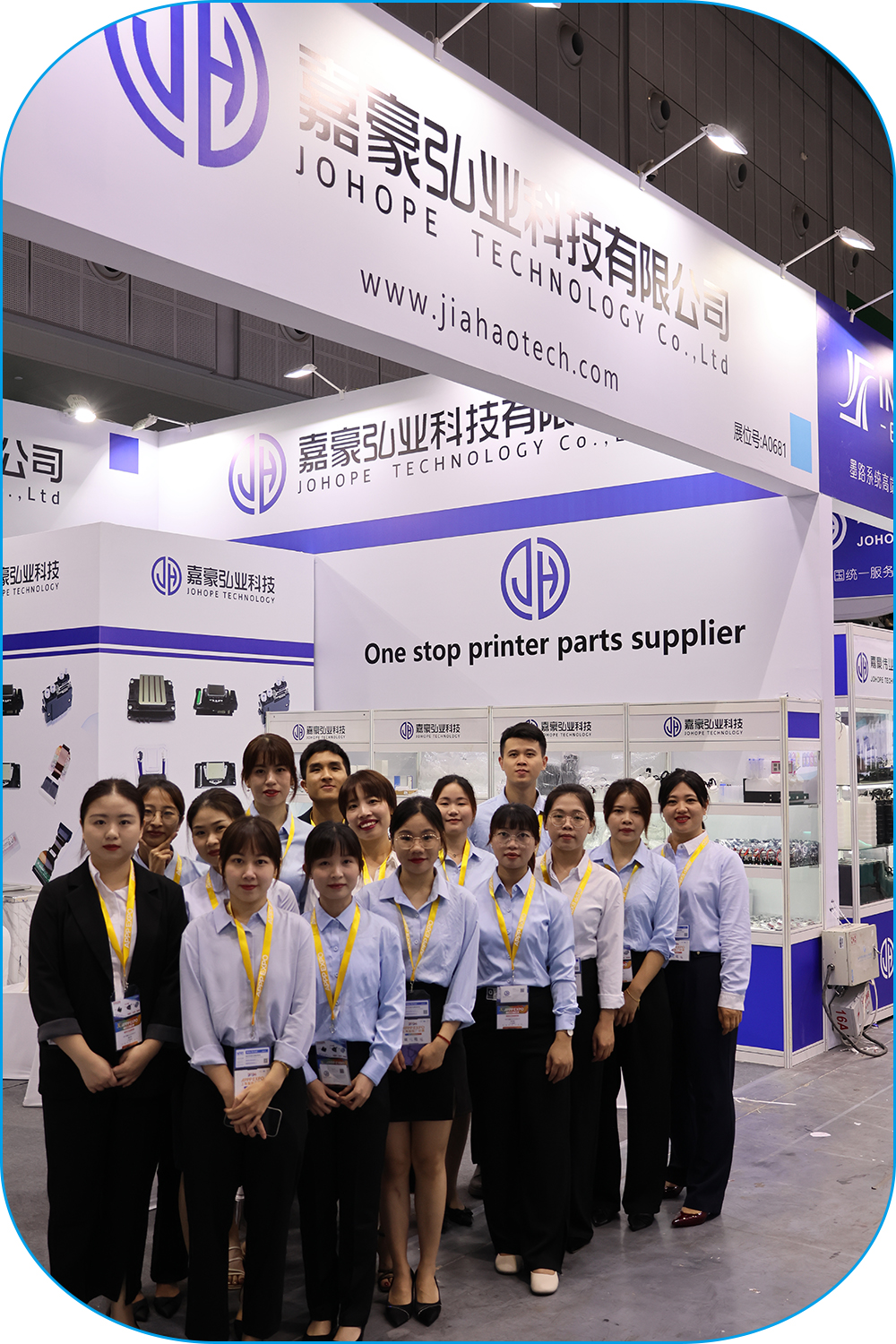

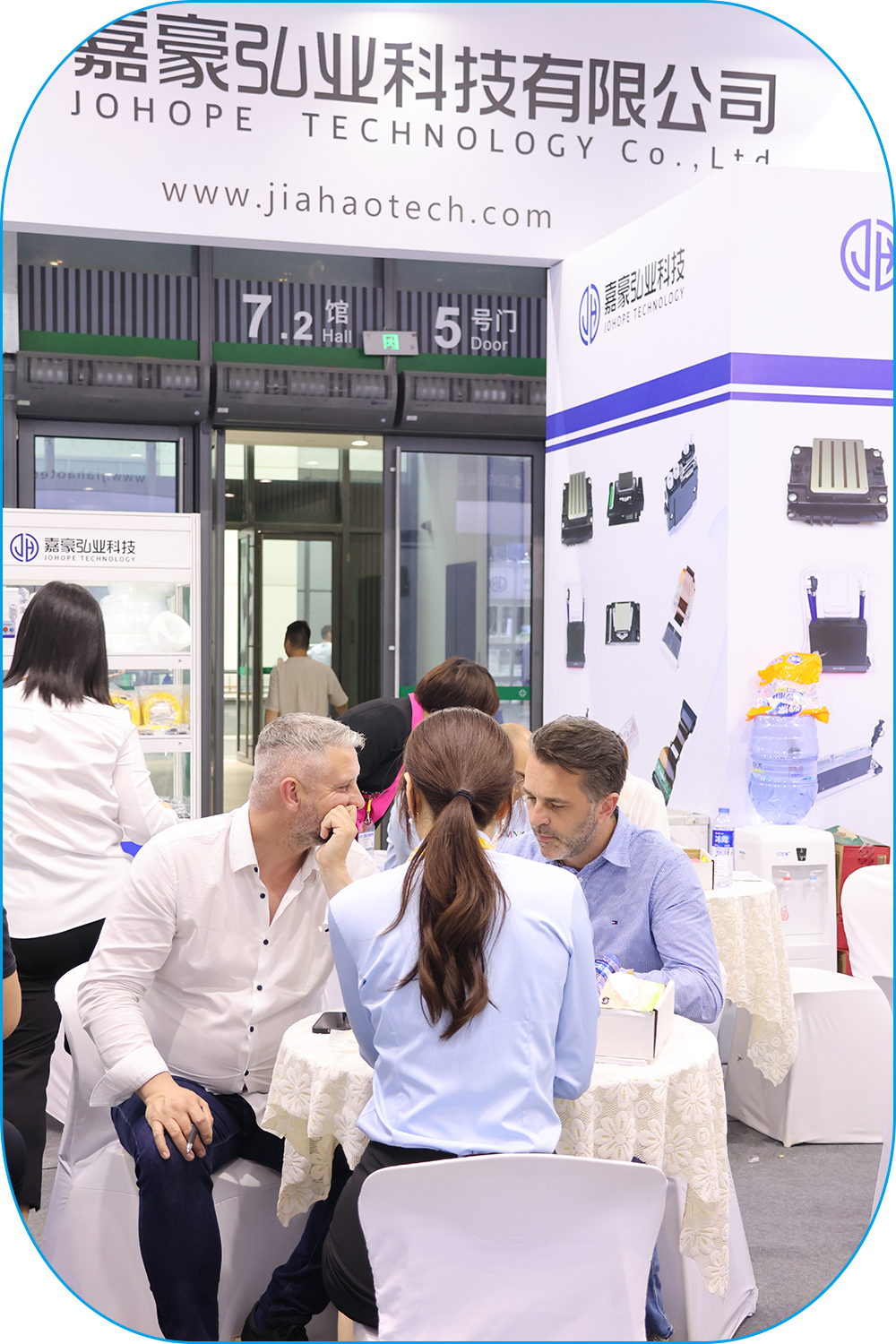

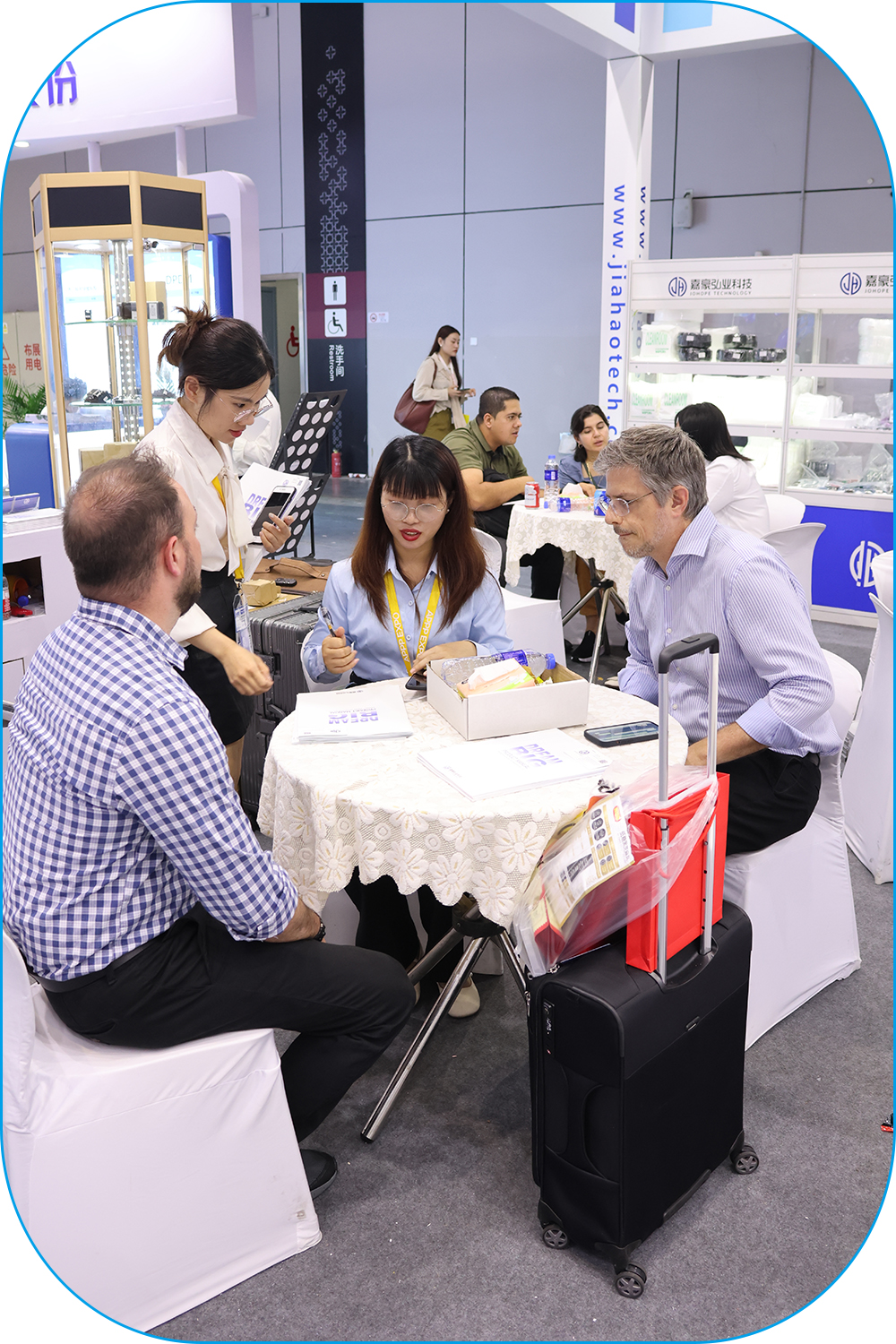

Exhibitions

As a leading manufacturer and supplier of spare parts for wide-format inkjet printers, Johope Technology actively participates in advertising exhibitions held around the world every year, such as FESPA, DPES, APPP EXPO, SIGN CHINA, SIGN ISTANBUL, and so on. For Johope Technology, every exhibition is an opportunity to increase brand awareness and explore new markets. They allow customers from home and abroad to understand our products and services better, increasing their trust and recognition. At the same time, we have also accumulated more experience in digital printer spare parts.