Leadshine Motor 57BL180D-1000

- Stock: 1000

- Model: 57BL180D-1000

- Weight: 1.50kg

- SKU: 06.02.01.002.002

Leadshine Motor 57BL180D-1000 Description

Constructed with top-quality materials, the Leadshine 57BL180 is a robust 180W brushless DC servo motor designed for industrial applications. The standard model features a 4,000 PPR (1000-line) incremental encoder, offering smooth, quiet operation with minimal heat generation in motion control systems.

When paired with Leadshine ACS series servo drives, it delivers the high torque required across a speed range from 1 to 3000 rpm. This flange-mounted motor is compatible with NEMA23 stepper motor mounts, making it a cost-effective solution for upgrading systems from stepper motors to brushless servos or replacing brushed DC servos. It provides servo-level performance—high speed, precision, low noise, and minimal heating—at a price comparable to standard stepper systems.

Leadshine Motor 57BL180D-1000 Specifications

- Brushless design for enhanced durability

- High-reliability industrial-grade quality

- 57mm screw-mount, 36 VDC rated, with 180W power output

- Features a 4000 CPR (1000-line) incremental encoder providing A and B signals

- Delivers 0.57 N-m (81 oz-in) rated torque and 1.71 N-m (243 oz-in) peak torque

- 3000 RPM rated speed with a 4000 RPM peak

- Standardized cabling options for direct integration with ACS series servo drives

Payment & Shipping

|

Shipping Method: |

DHL, FedEx |

Delivery Time: |

1~3 Workdays |

|

Lead Time: |

7 days or more |

Delivery Time: |

PayPal |

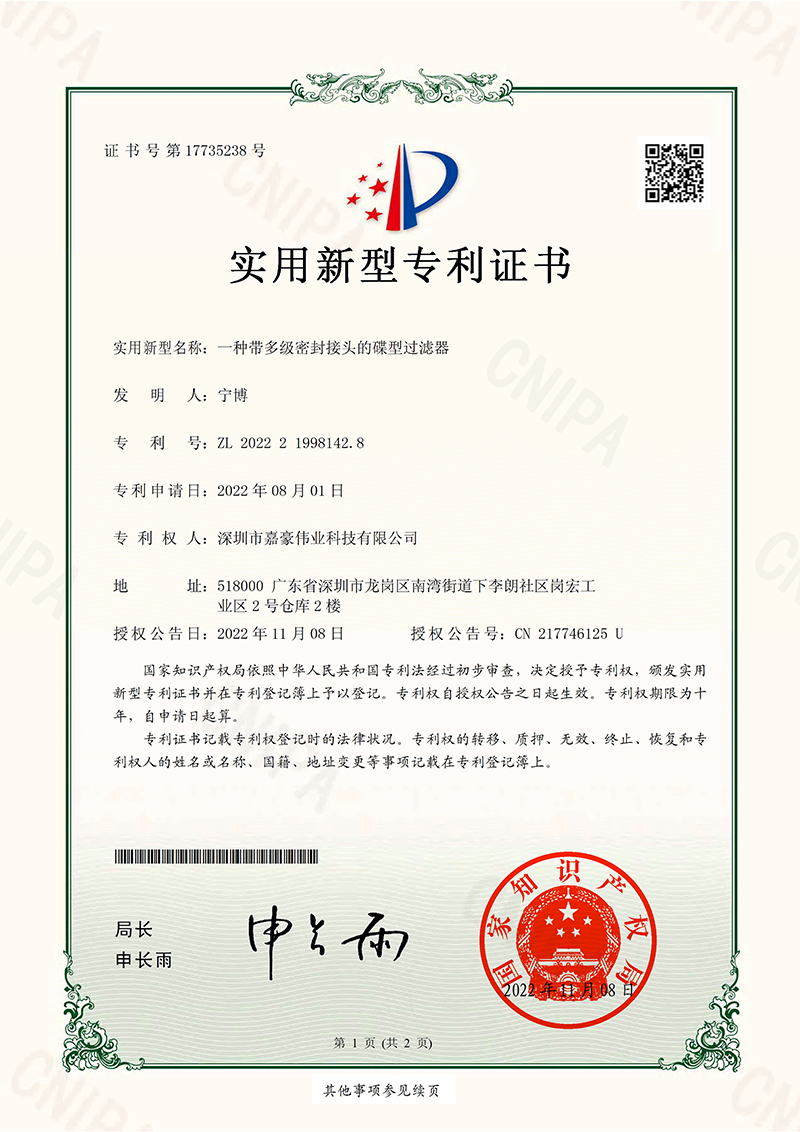

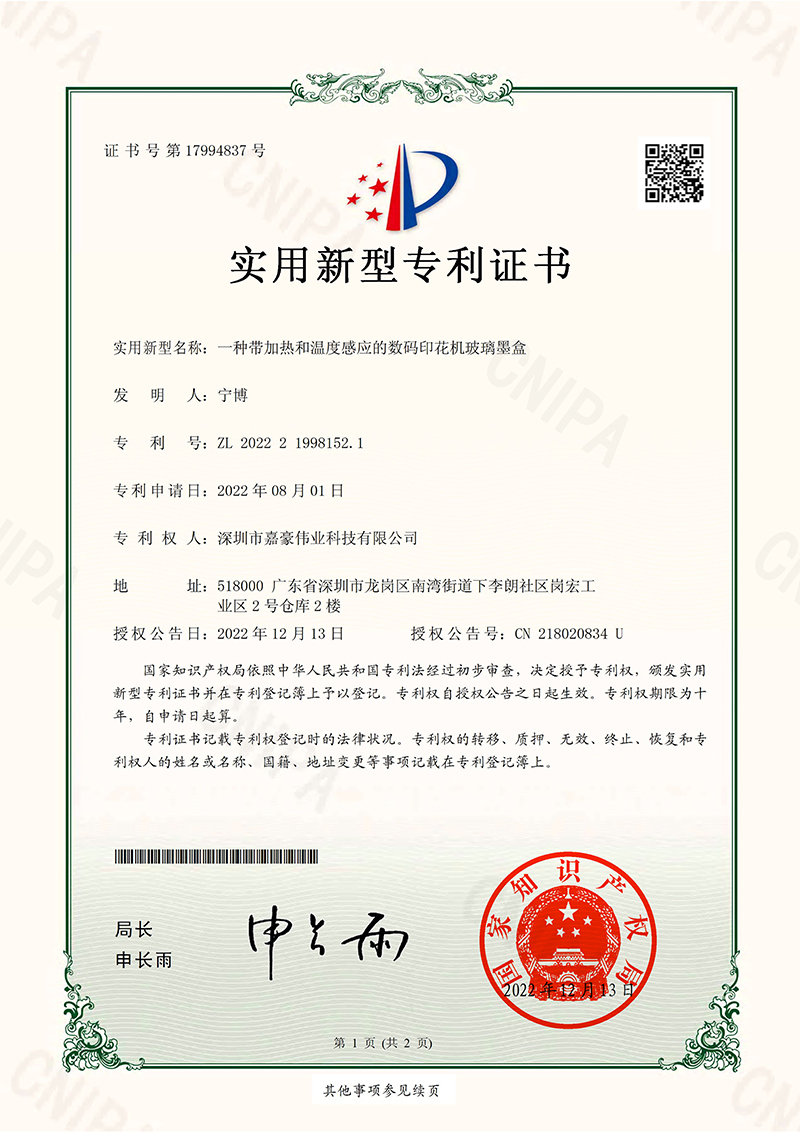

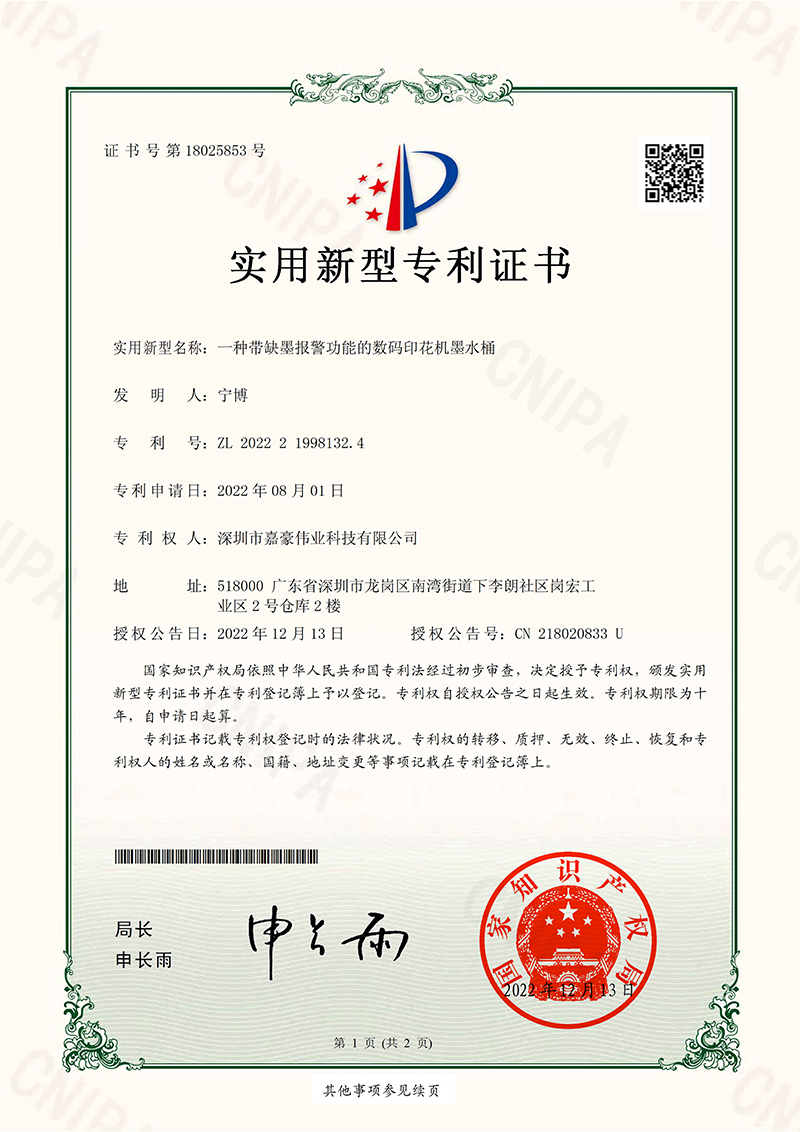

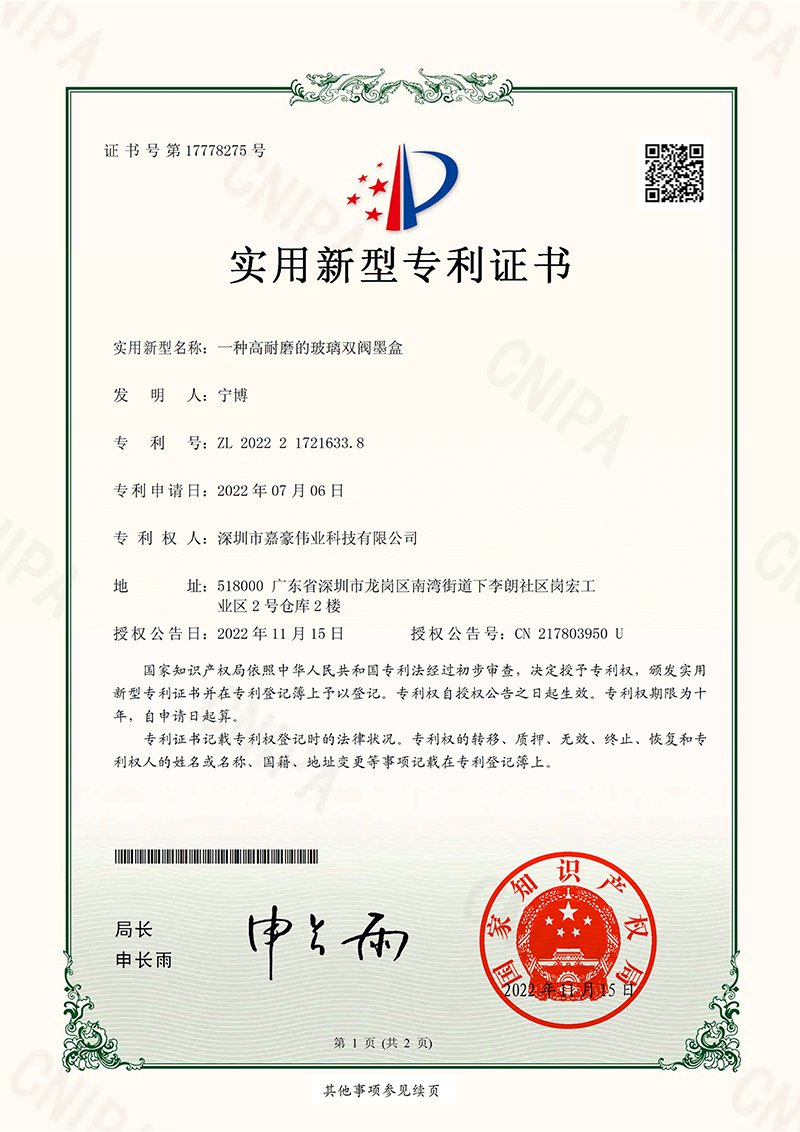

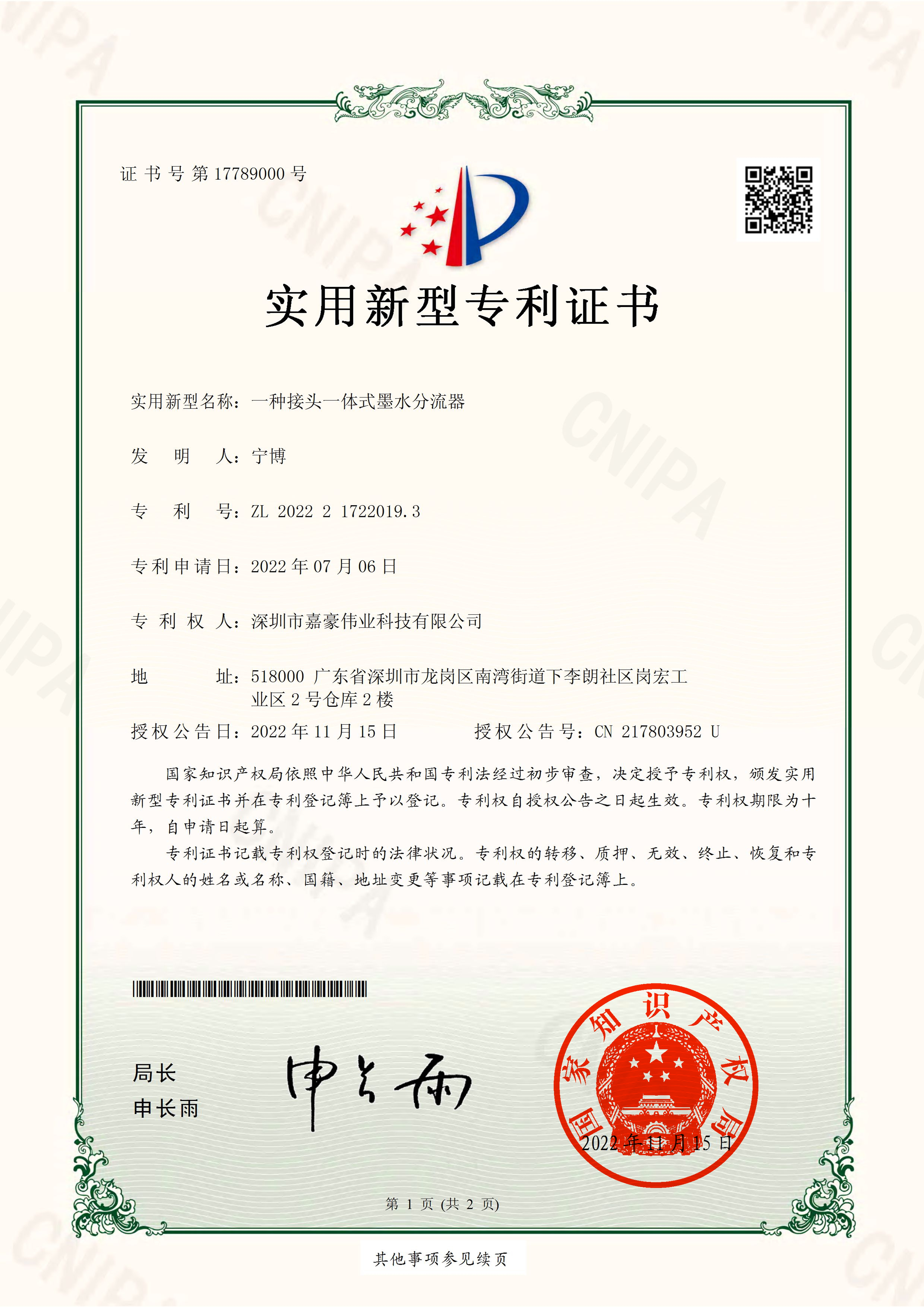

Certifications

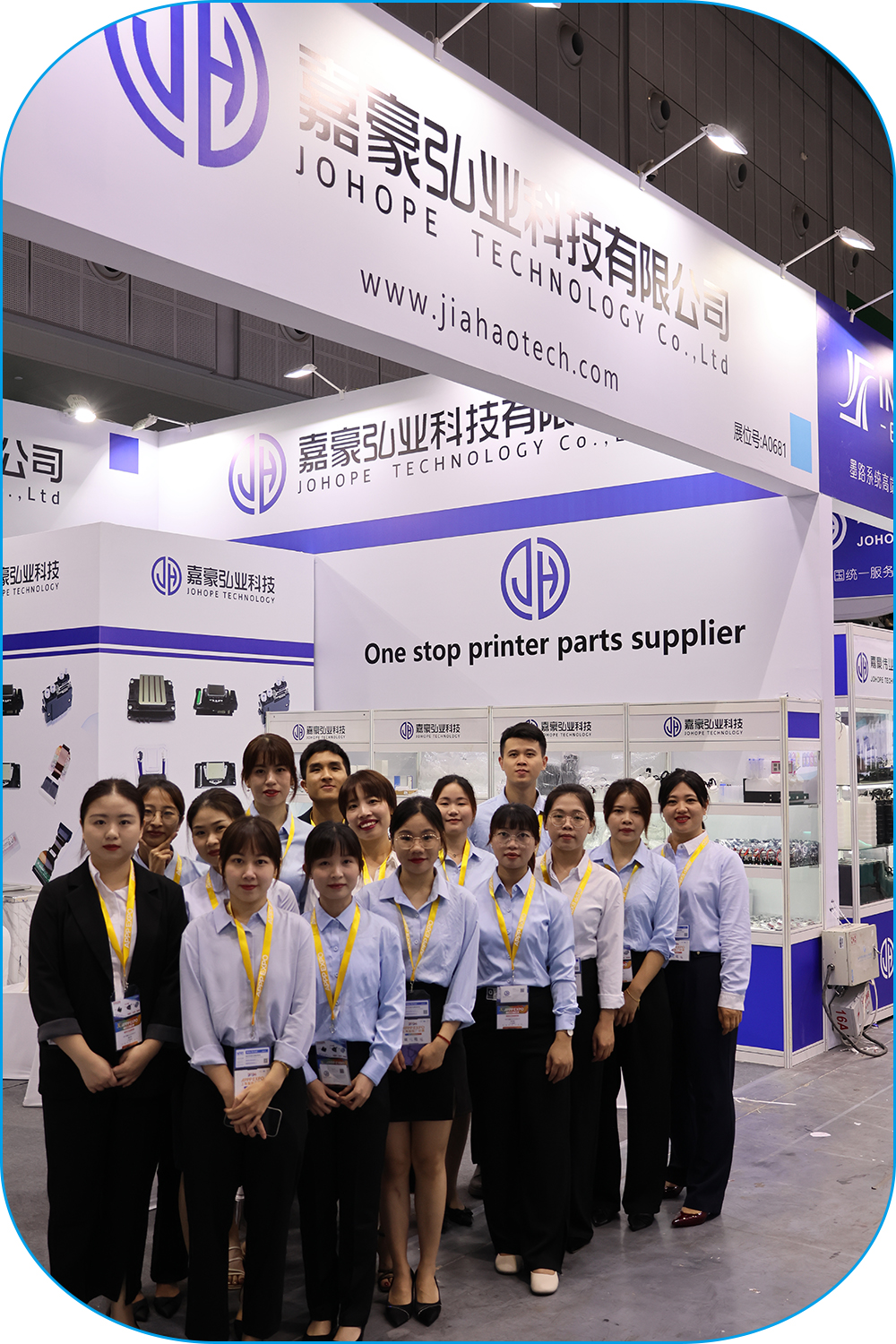

Why Choose JOHOPE?

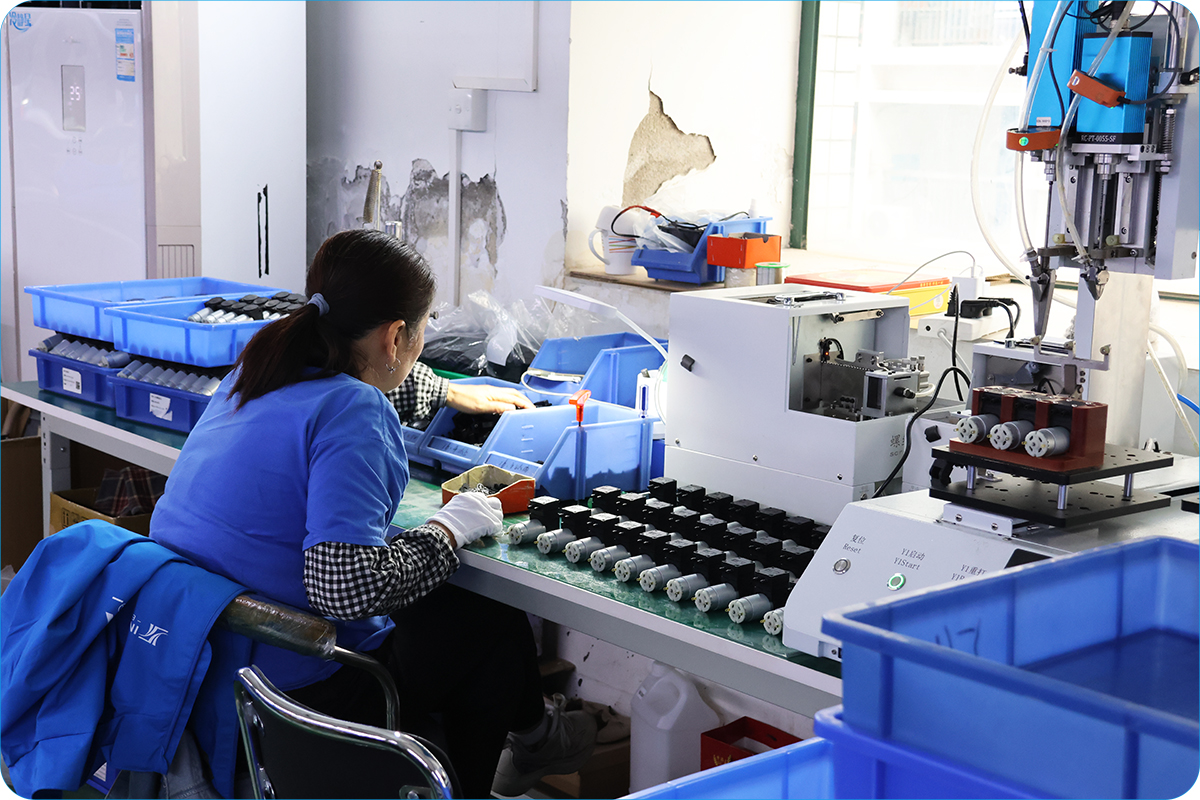

01 Professional Production Lines

- 5000+ high-quality products meet customers' specific requirements.

- Skilled workforce complies with standard production procedures & processes.

- R&D personnel possess extensive knowledge of printer ink supply parts.

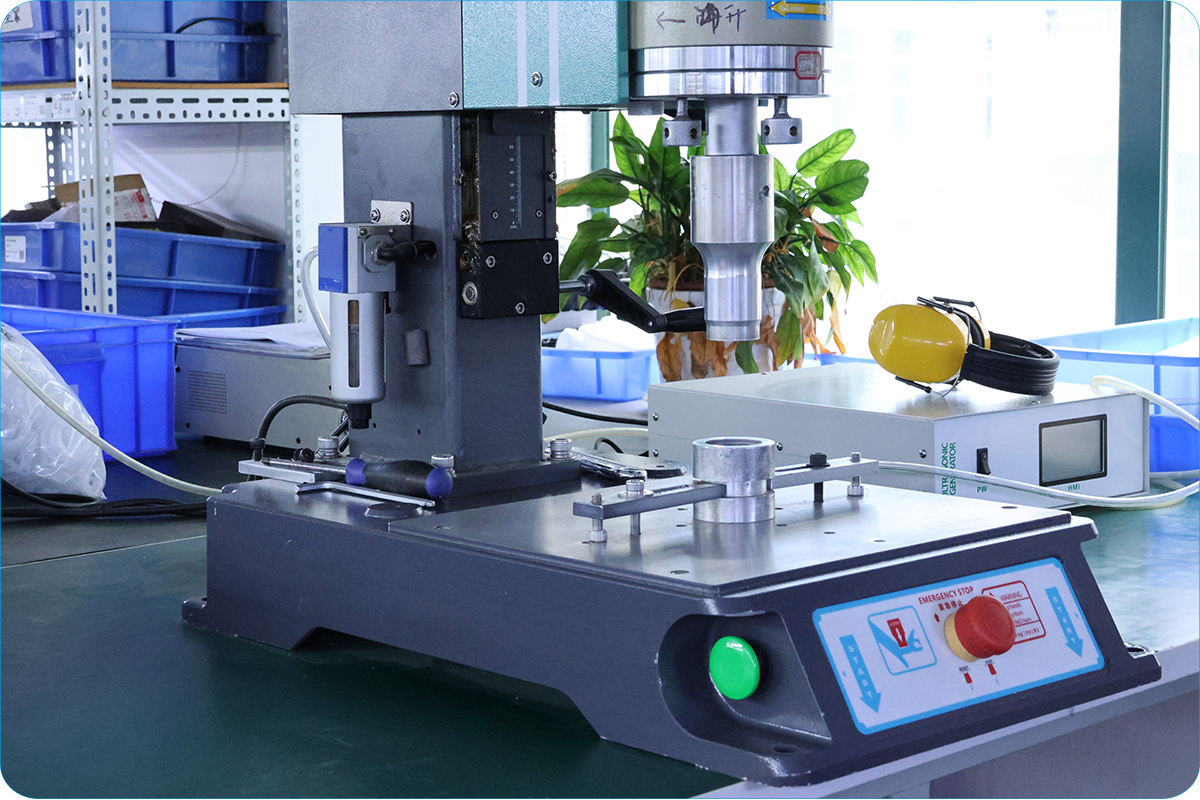

02 Automated Production Equipment

- Our company boasts cutting-edge production equipment that ensures precision and efficiency in every manufacturing process.

- The advanced machinery and production patent technology allow us to consistently deliver high-quality products that meet the demands of our clients.

03 Logistics and Warehousing

- Manage warehousing facilities to ensure product safety and traceability.

- Our warehouse covers a large area to ensure a complete inventory of products, realizing high product shipment efficiency.

- Years of production and sales experience have been highly recognized and praised by customers in the industry.

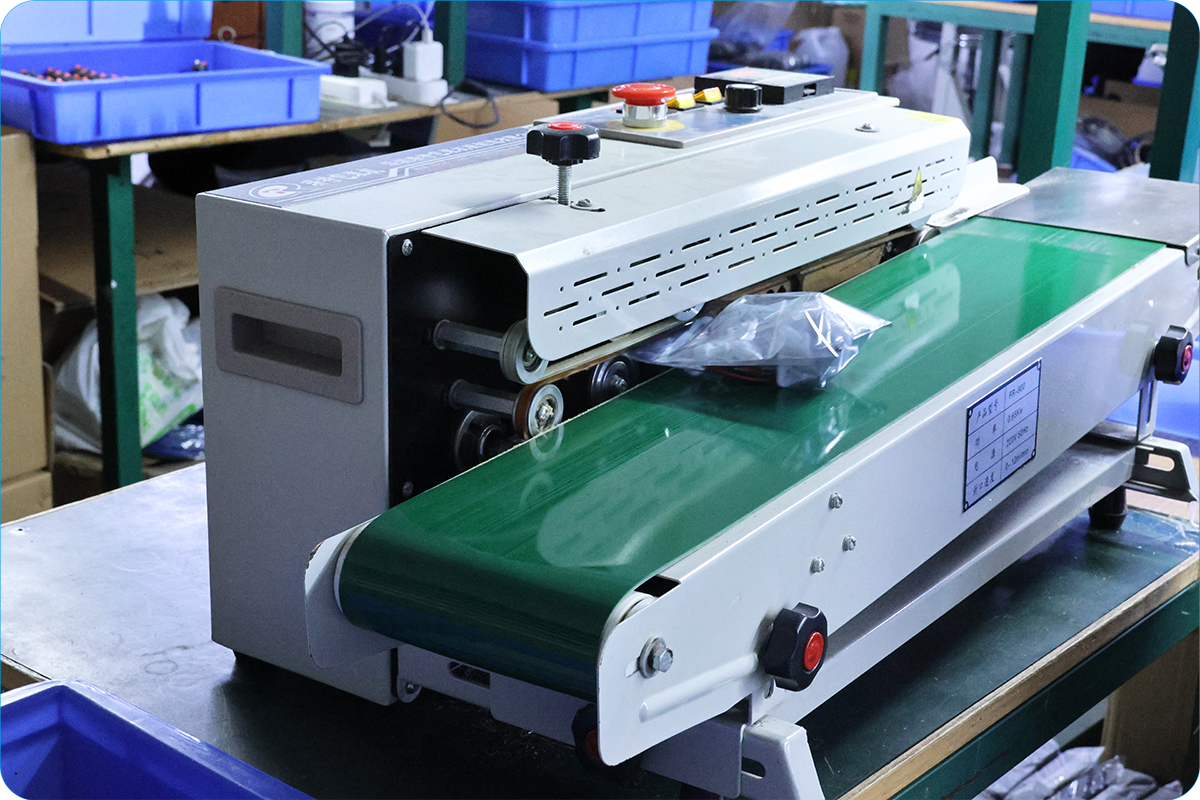

04 Packaging and Quality Inspection

- Our packaging solutions are designed with durability and precision to ensure each product is securely protected during transit.

- We use high-quality materials and advanced techniques to meet the specific needs of every order, guaranteeing safe and reliable delivery.

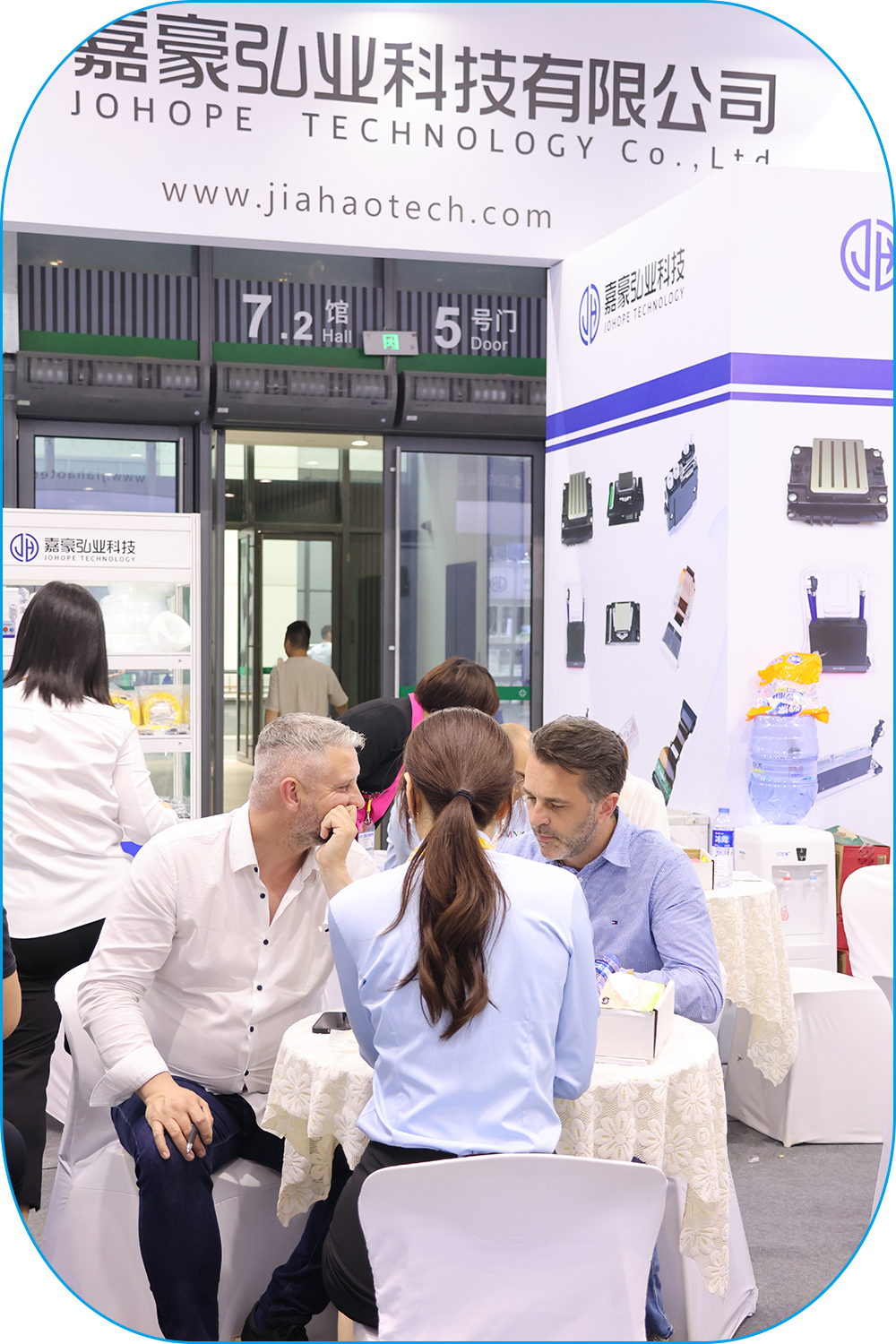

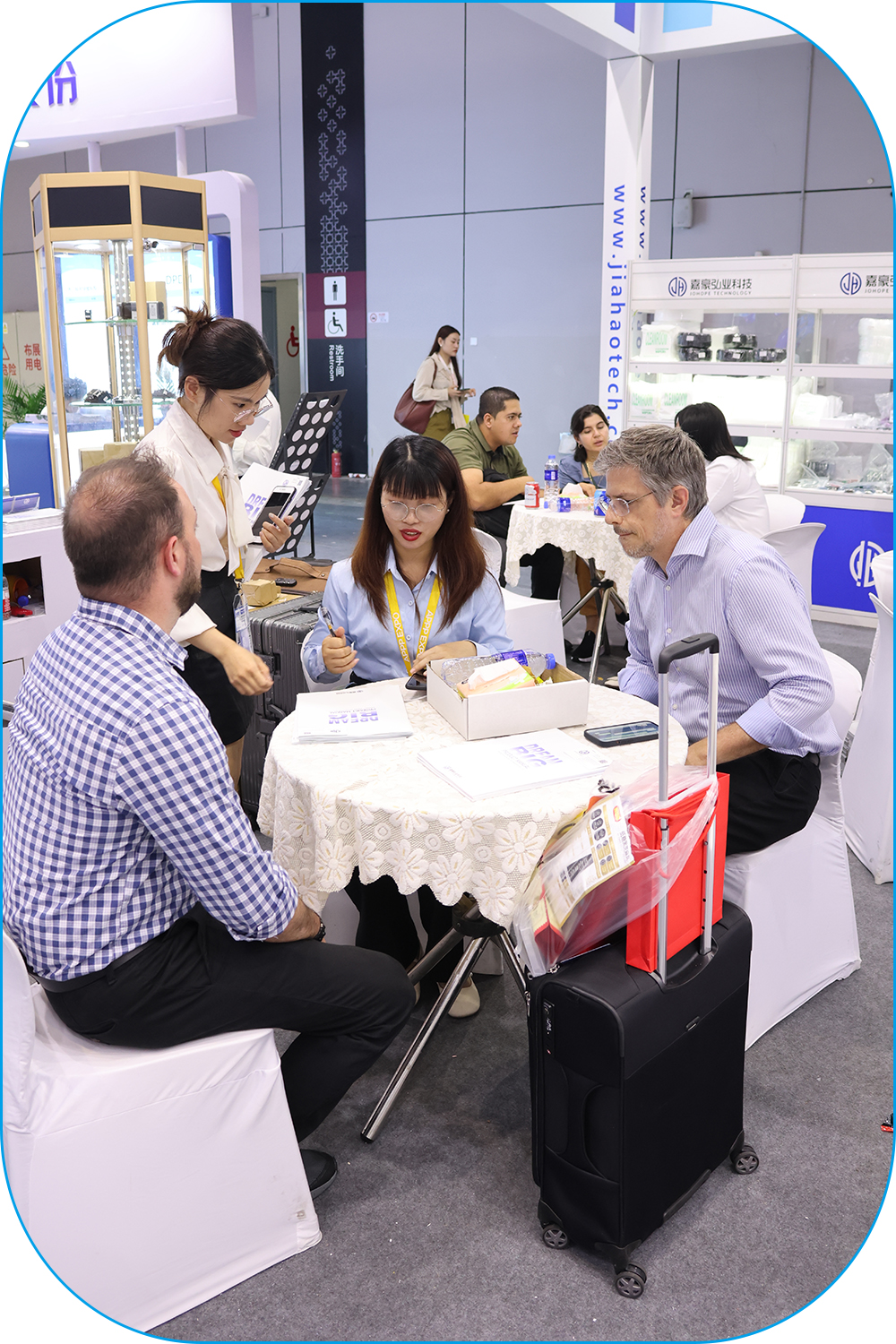

Exhibitions

As a leading manufacturer and supplier of spare parts for wide-format inkjet printers, Johope Technology actively participates in advertising exhibitions held around the world every year, such as FESPA, DPES, APPP EXPO, SIGN CHINA, SIGN ISTANBUL, and so on. For Johope Technology, every exhibition is an opportunity to increase brand awareness and explore new markets. They allow customers from home and abroad to understand our products and services better, increasing their trust and recognition. At the same time, we have also accumulated more experience in digital printer spare parts.