Epson Printhead Cleaner for DX5/DX7/XP600/TX800/5113/4720

- Stock: 100

- Model: Epson Printhead Cleaner

- Weight: 5.00kg

- SKU: 10.05.01.001.001

Epson Printhead Cleaner Description

Epson printhead Cleaning Machine Operation Guide

Notes: After removing the printhead, clean the remaining ink and the surface first to prevent the filter from clogging prematurely.

1. Open the bottom cover of the machine and the lid of the cleaning liquid storage tank.

2. Pour the cleaning liquid into the cleaning liquid storage tank, and the minimum amount should cover the water outlet of the tank.

3. Cover the lid of the cleaning liquid storage tank and then cover the bottom cover of the cleaning machine.

4. Open the top cover of the machine and install the printhead support frame on the machine.

5. Connect the ink inlet of the printhead to the flushing pipe of the cleaning machine.

6. Clamp the printhead to the printhead support frame.

7. Pour the cleaning liquid into the cleaning tank until the liquid level is close to the reflux port, and adjust the height of the printhead. It is best to have the nozzle of the printhead 2mm below the liquid level.

8. Press the red button on the machine to start ultrasonic cleaning. The ultrasonic start time is about 60 seconds.

9. Press the green button corresponding to the printhead connection pipeline to let the cleaning liquid circulate and flush it.

10. After turning off the ultrasonic wave, you can pick up the printhead and observe the cleaning effect.

11. Repeat the cleaning several times, and then change to clean cleaning liquid to clean until the cleaning liquid ejected from the nozzles is neat during flushing. After cleaning, clean the printhead and reinstall the printer.

Tips:

Do not turn on the ultrasonic wave more than 15 times a day, with an interval of 2-3 minutes each time. If the cleaning effect is not good on the same day, soak it for a day and repeat the operation.

Epson Printhead Cleaner Specifications

|

Printhead Cleaner |

||||

|

Item/Model |

General Type |

UV Type |

Ceramic Type |

E Type |

|

Input Voltage/Frequency |

Default 22oV (Option 110V) 40-60Hz |

|||

|

Power Consumption |

50W |

50W |

80W |

50W |

|

Ultrasonic Power |

35W/40KHz |

35W/40KHz |

80W/40KHz |

35W/40KHz |

|

Flow |

300ML/MIN |

500ML/MIN |

600ML/MIN |

500ML/MIN |

|

N.W/G.W |

4.5KG/5KG |

4.5KG/5KG |

5.5KG/6KG |

4.5KG/5KG |

|

Packing Measurement |

L 34CM’ W28CM’ H31CM |

|||

Payment & Shipping

|

Shipping Method: |

DHL, FedEx |

Delivery Time: |

1~3 Workdays |

|

Lead Time: |

7 days or more |

Delivery Time: |

PayPal |

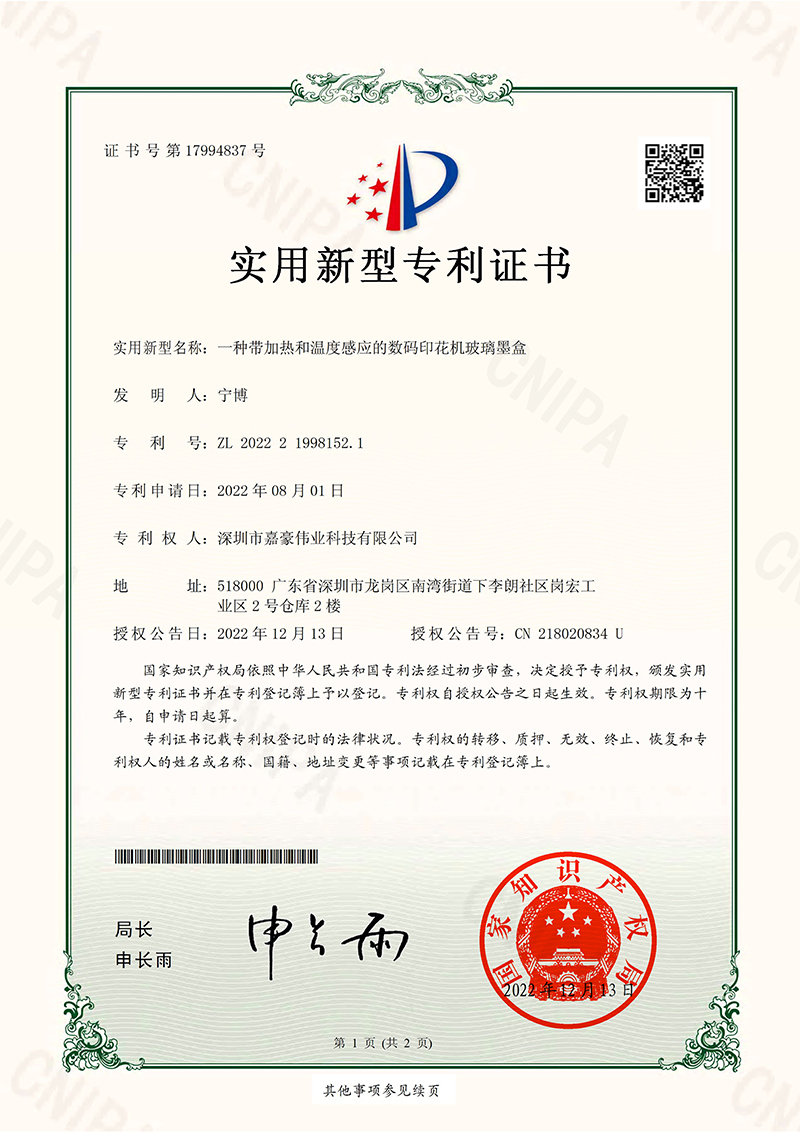

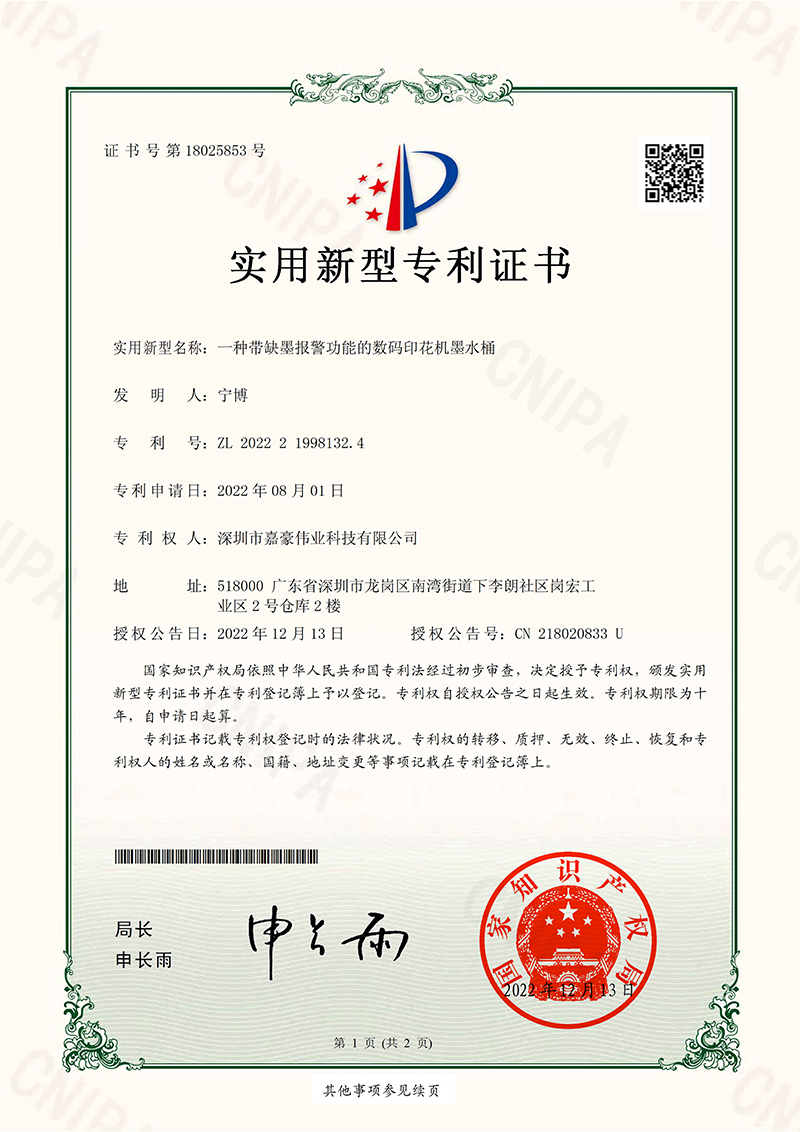

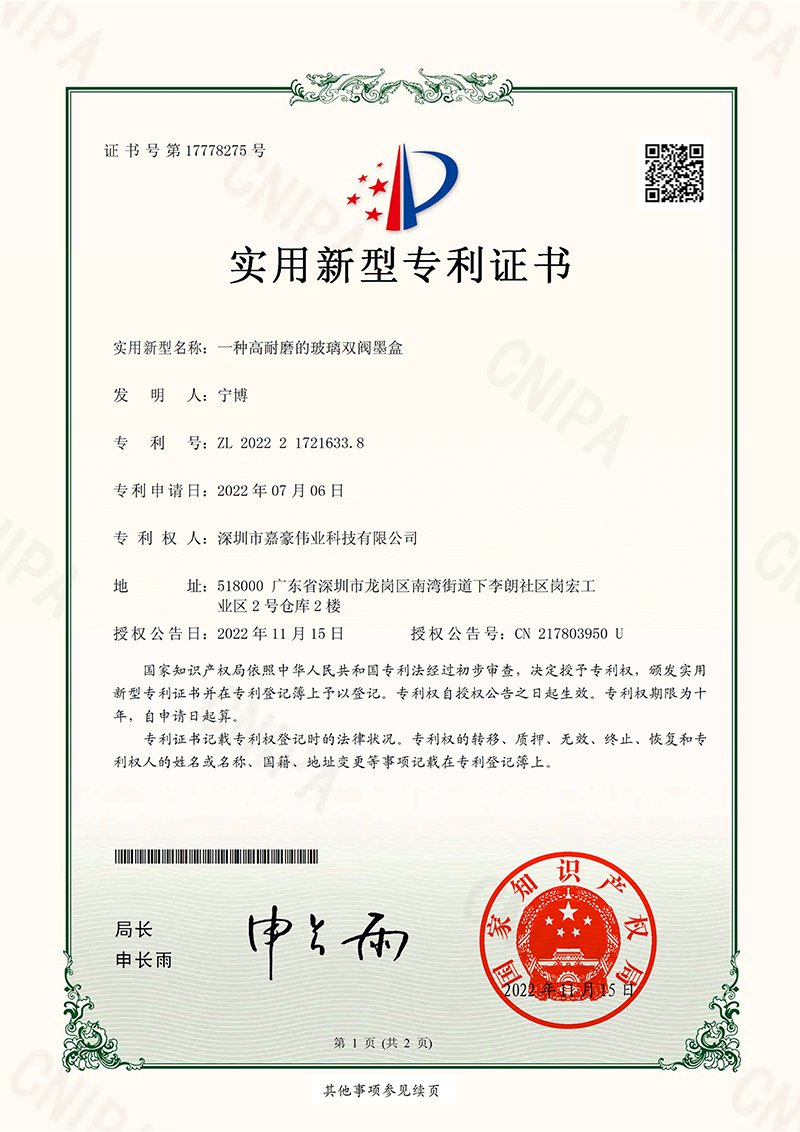

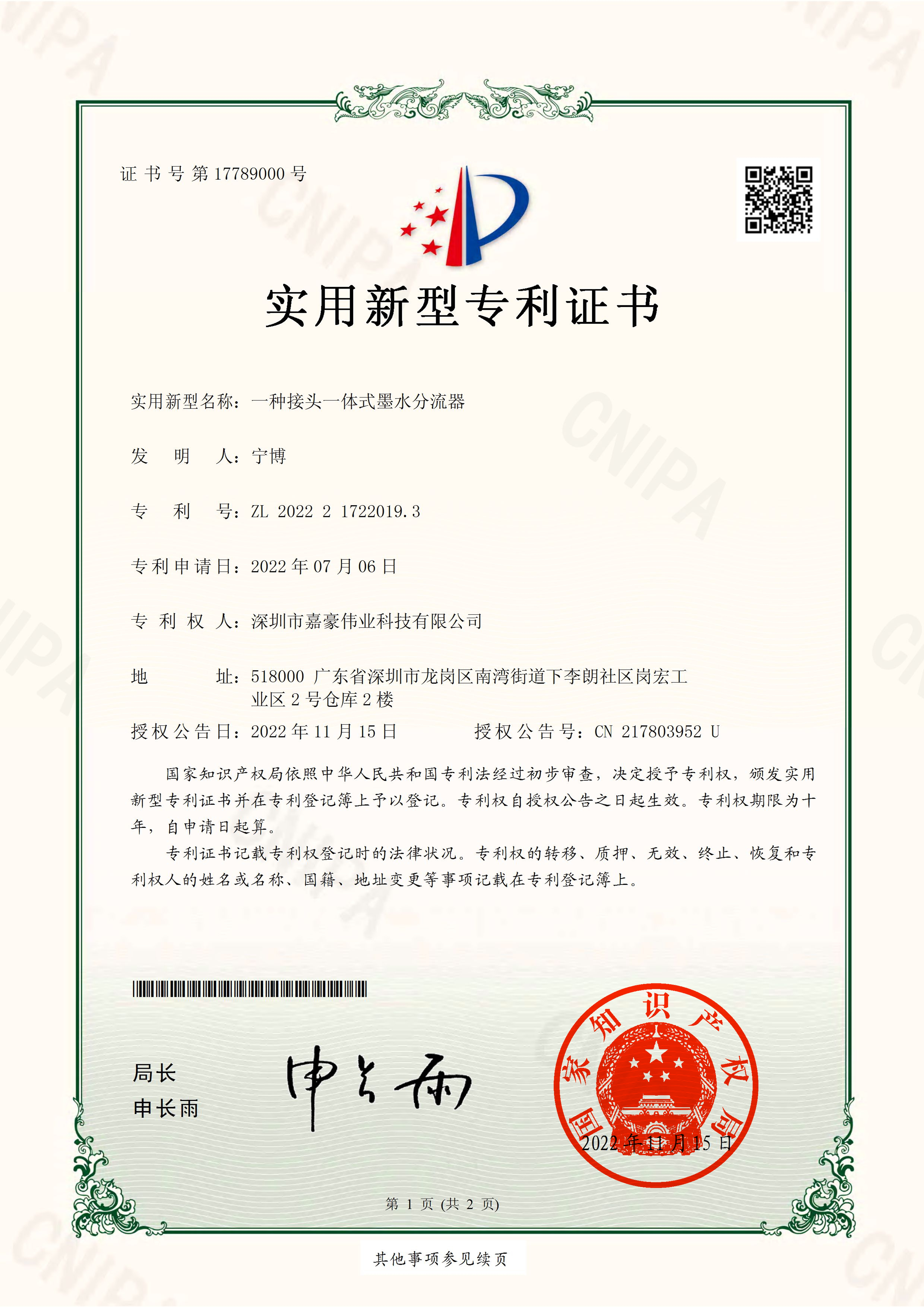

Certifications

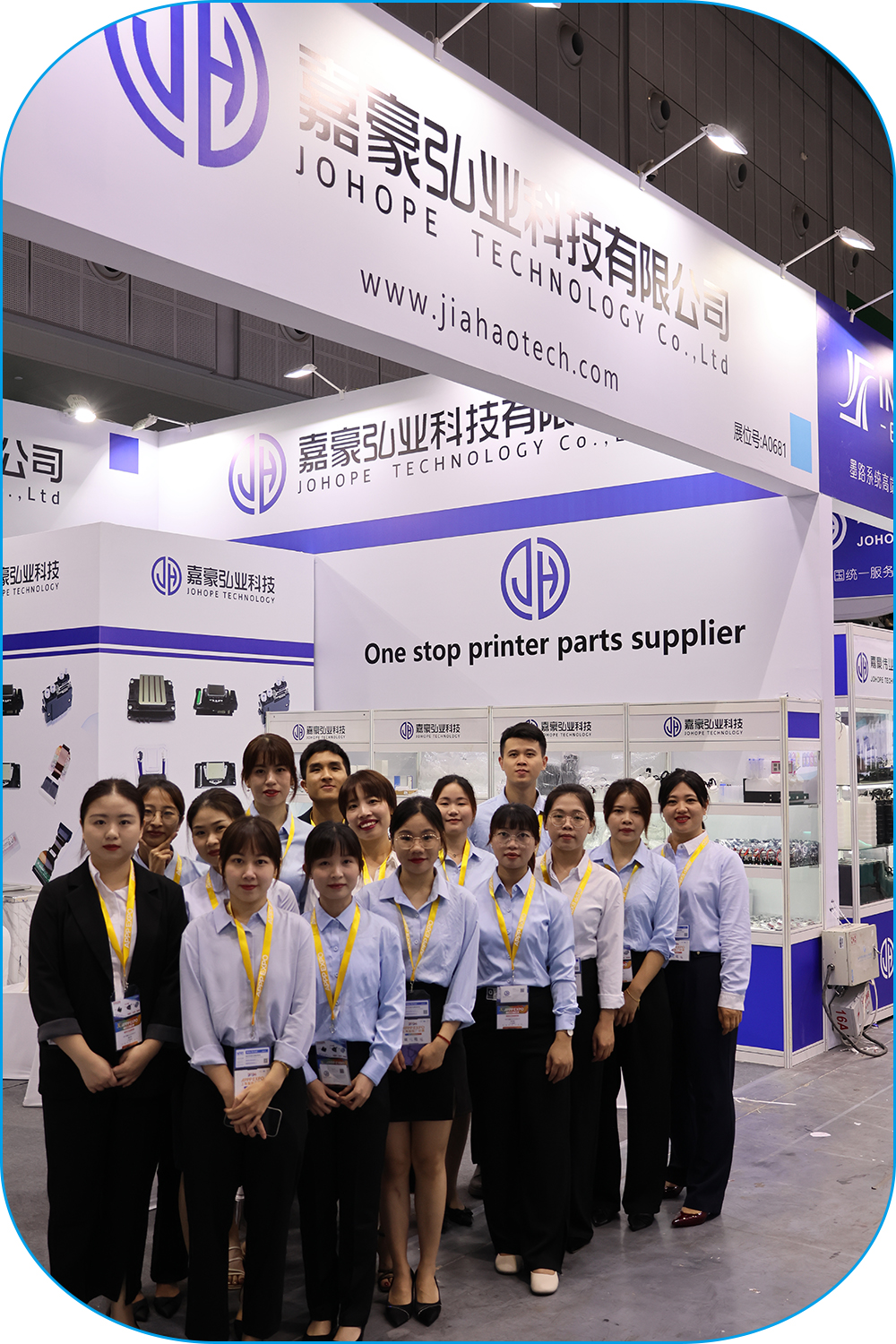

Why Choose JOHOPE?

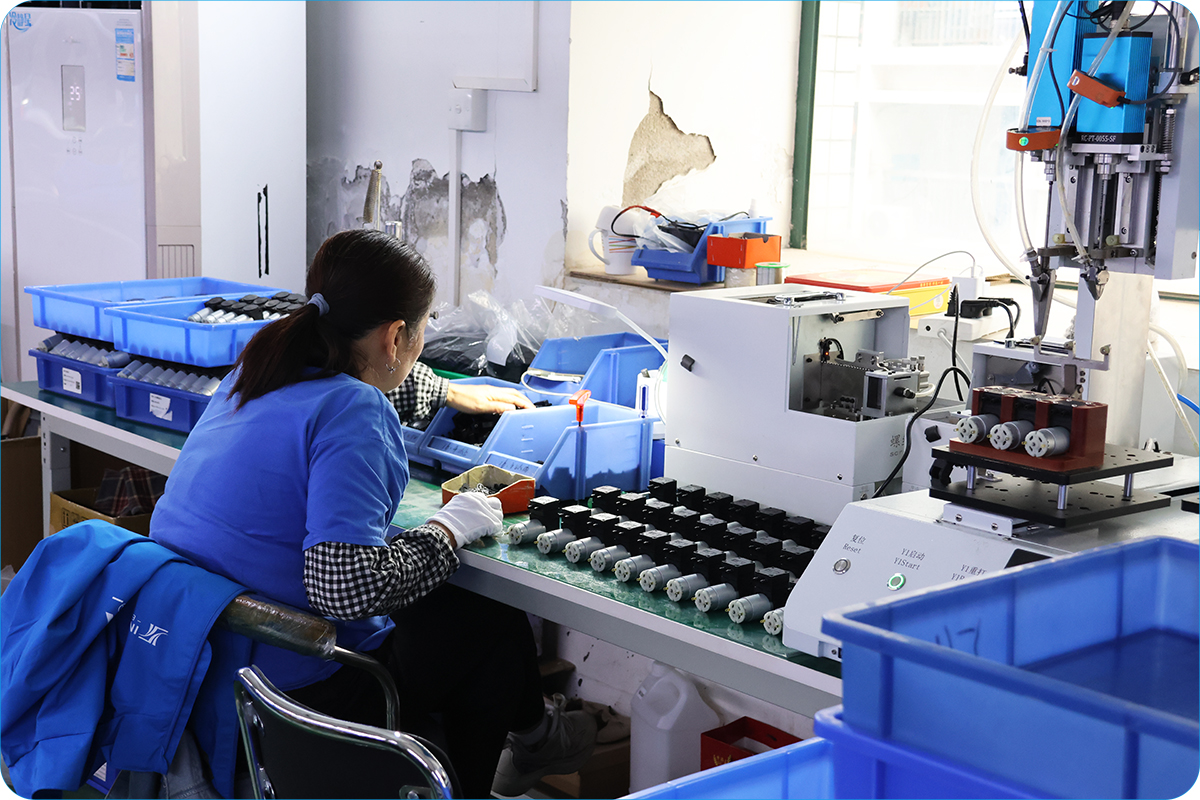

01 Professional Production Lines

- 5000+ high-quality products meet customers' specific requirements.

- Skilled workforce complies with standard production procedures & processes.

- R&D personnel possess extensive knowledge of printer ink supply parts.

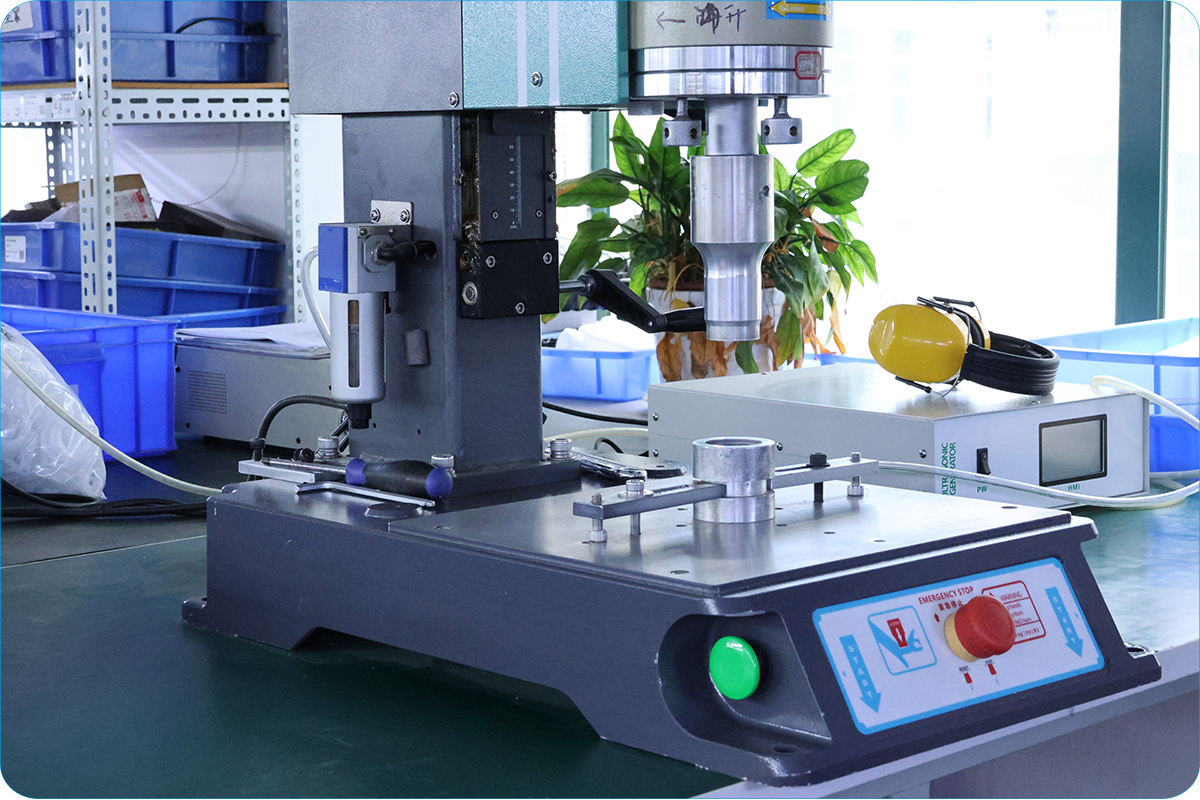

02 Automated Production Equipment

- Our company boasts cutting-edge production equipment that ensures precision and efficiency in every manufacturing process.

- The advanced machinery and production patent technology allow us to consistently deliver high-quality products that meet the demands of our clients.

03 Logistics and Warehousing

- Manage warehousing facilities to ensure product safety and traceability.

- Our warehouse covers a large area to ensure a complete inventory of products, realizing high product shipment efficiency.

- Years of production and sales experience have been highly recognized and praised by customers in the industry.

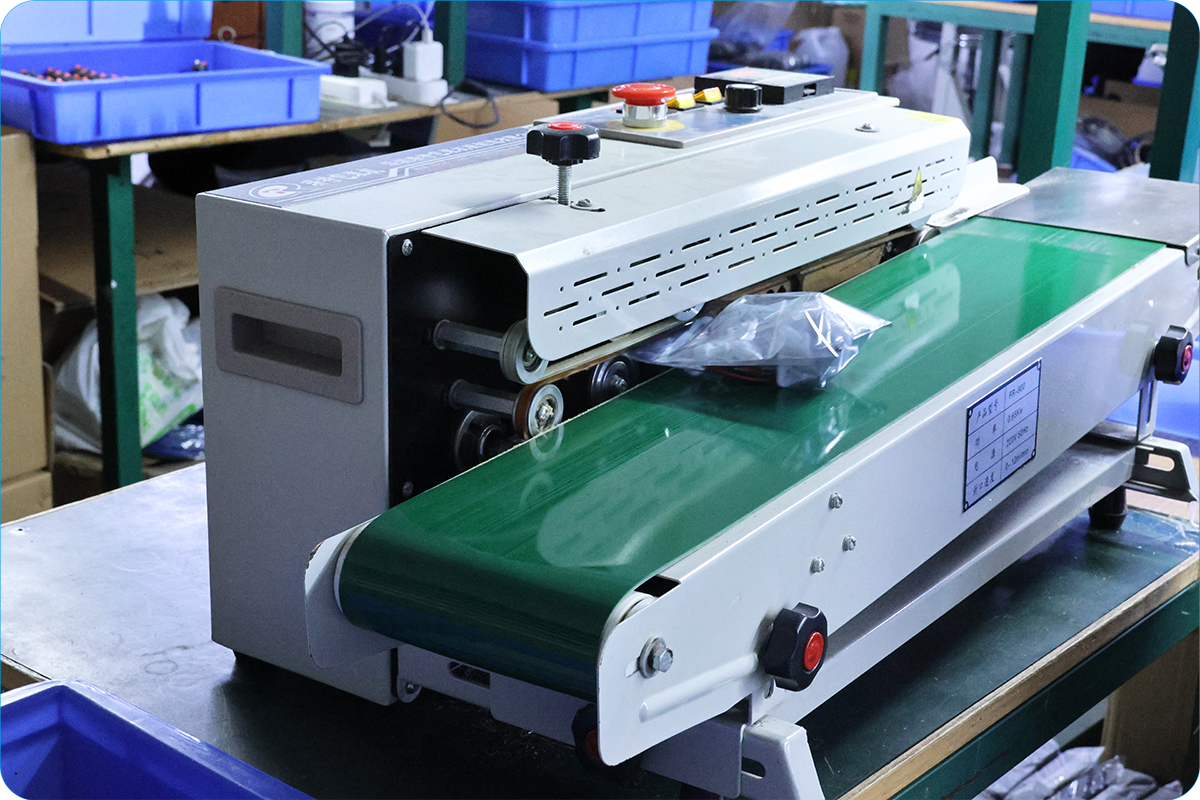

04 Packaging and Quality Inspection

- Our packaging solutions are designed with durability and precision to ensure each product is securely protected during transit.

- We use high-quality materials and advanced techniques to meet the specific needs of every order, guaranteeing safe and reliable delivery.

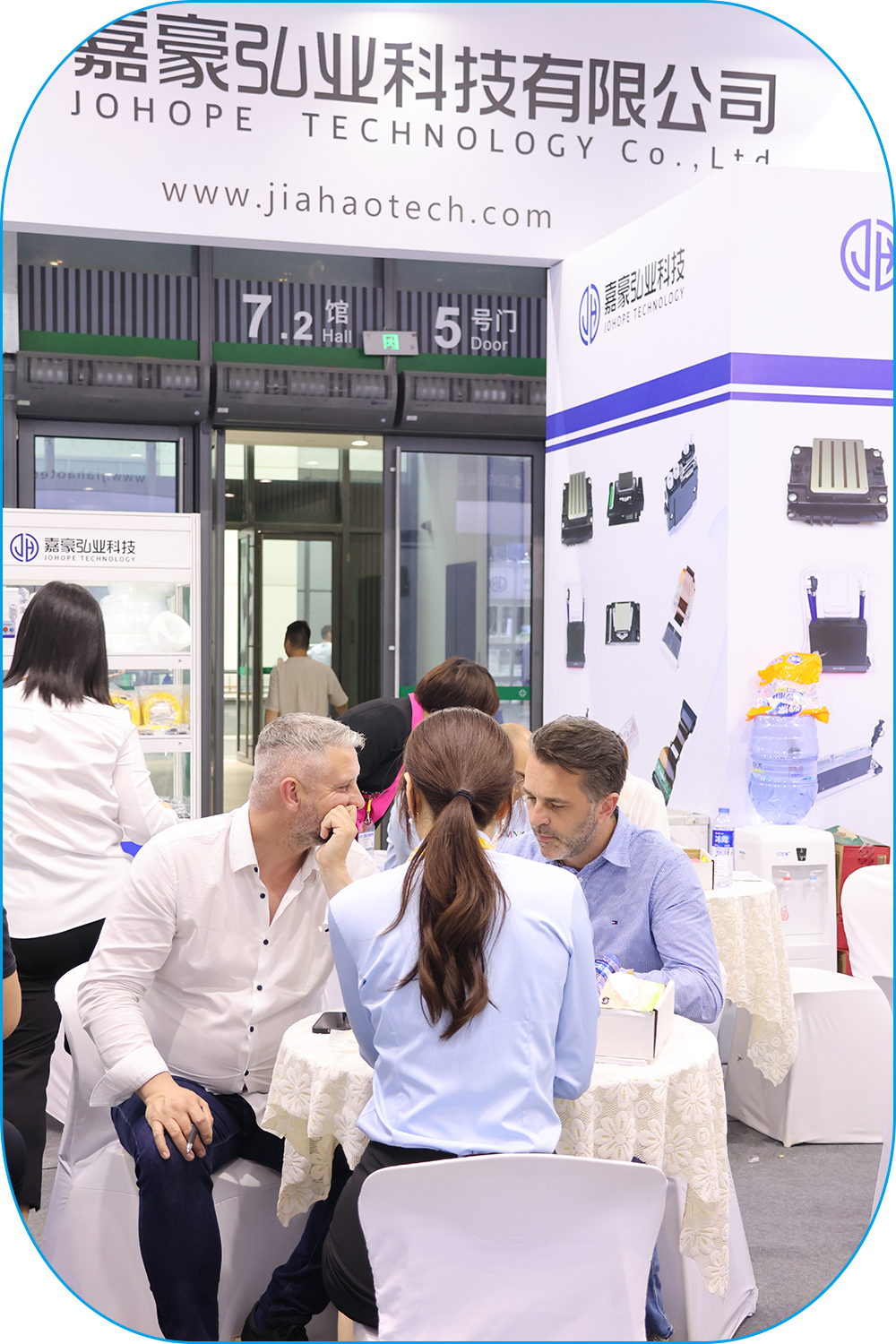

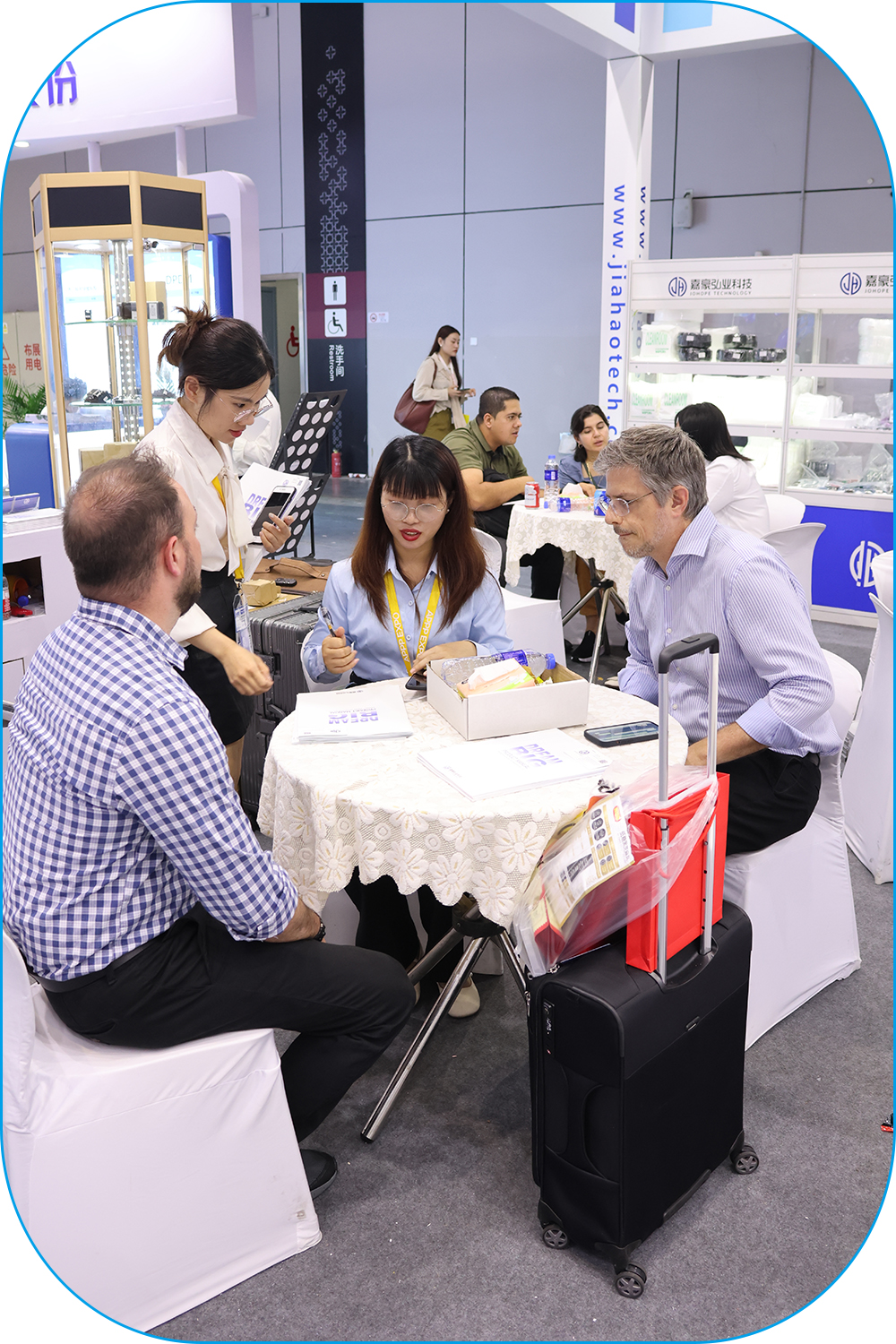

Exhibitions

As a leading manufacturer and supplier of spare parts for wide-format inkjet printers, Johope Technology actively participates in advertising exhibitions held around the world every year, such as FESPA, DPES, APPP EXPO, SIGN CHINA, SIGN ISTANBUL, and so on. For Johope Technology, every exhibition is an opportunity to increase brand awareness and explore new markets. They allow customers from home and abroad to understand our products and services better, increasing their trust and recognition. At the same time, we have also accumulated more experience in digital printer spare parts.